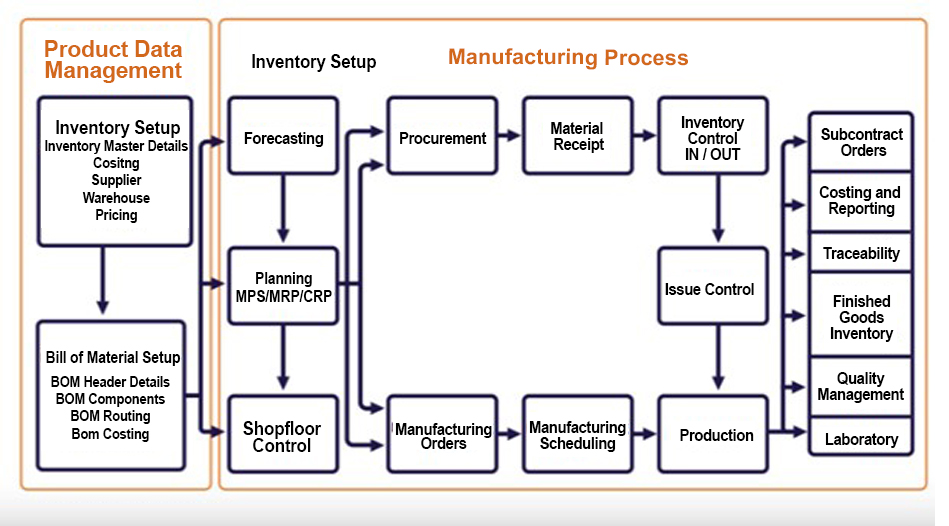

A Good Manufacturing solution integrates people & technology to generate competitive advantage

Solution Overview

Manufacturing

Our Manufacturing solution ensure operations are lean, expandable, and cost saving. Our manufacturing help businesses to leverage on Shopfloor Manufacturing, Manufacturing Planning, Manufacturing Scheduler, Laboratory and Quality Management to optimize production and reduce waste/cost.

>30 manufacturing customers across ASEAN

20 years of manufacturing experience

SME specialization

Discreet and Non discreet manufacturing

Manufacturing with smart integrations

Fundamental Modules for Manufacturing

-

Bill of Materials Supports

Bill of Materials Supports -

Shopfloor

Shopfloor -

Scheduler

Scheduler -

Manufacturing Planning

Manufacturing Planning

Bill of Materials BOM

The bill of materials supports up to 50 levels of sub assembly bill of structures required to produce the parent assembly. Different types of bill can be built to meet product lifecycle. The BOM solution also delivers cost roll-up production factory, and where the same BOM exists across multiple factories.

Shopfloor

The bill of materials supports up to 50 levels of sub assembly bill of structures required to produce the parent assembly. Different types of bill can be built to meet product lifecycle. The BOM solution also delivers cost roll-up production factory, and where the same BOM exists across multiple factories.

Work orders are typically used to manage the planning, execution, raw materials consumption and feedback of production results.

In a lean manufacturing environment, Pronto Xi offers orderless and paperless recording of production, using backflush methods for raw materials consumption and progressive crediting of labour and overhead “hours earned”.

Special work order types and processes are available for disassembly-type industries and other special operations such as rework, repack and others.

Production results can be recorded using standard production feedback tools, or one of a large number of industry-specific production entry methods.

Shopfloor Manufacturing allows you to select a specific route from a predefined range on the day of actual production. Changes to the route ID can also be made against an open work order, whether at “firm planned” or “committed” status. This gives greater flexibility if quick changes to individual word orders are needed when production has not yet commenced. Lot, batch and serial tracking are supported for finished goods as well as components or raw materials.

Manufacturing Planning

Pronto Xi Manufacturing Planning provides a range of tools that optimise materials and capacity planning over single or multiple sites, and match the level of complexity required by the business. Here are key features:

Production Planning (PP)

Master Production (MPS)

Rough-Cut Capacity (RCCP)

Material Requirements Planning (MRP)

Capacity Requirements Planning (CRP)

Smart Manufacturing Integration

-

Mobile Production

-

IOT

-

RPA

-

SCM

Benefits

Smart Manufacturing requires a strong and integrated ERP system. Both Infor M3 and Pronto Xi Manufacturing modules are capable to extend its smart integration to our advanced application.

- Mobility increases the capabilities to track production anywhere and anytime

- IOT improves the visual performance of your machinery, which in return help to monitor your performance of output production.

- RPA helps to automate your application processes to streamline your process in manufacturing

- Analytics provides and understanding of data towards your production input and output

- Supply Chain Optimization further improves the capabilities of your production from demand planning to inventory optimizing within the given constraints.

Customers In Manufacturing

Manufacturing ERP FAQs

A Production ERP is an enterprise system designed specifically for manufacturing operations that cover planning, scheduling, shop-floor execution, materials management and cost roll-up. SL Information emphasises that their manufacturing solution supports BOM up to 50 levels, alternative routing and lot/batch/serial tracking.

By using a Production ERP, your company can improve visibility, reduce waste, and become more responsive.

Key modules for a Manufacturing ERP include:

- Bill of Materials (BOM) and sub-assemblies.

- Scheduler and planning tools (MRP, RCCP, CRP).

- Shop-floor manufacturing and work-order execution.

- Malaysia Software Solutions Provider

- Quality management, traceability, lot/batch control. (especially relevant for Production ERP)

These modules help ensure the system optimises production, rather than just supporting generic business functions.

SL Information has more than 20 years of manufacturing domain experience and a track record of serving over 30 manufacturing customers across ASEAN.

We specialize in both discrete and non-discrete manufacturing, and emphasise smart integrations (IoT, mobile, RPA) which makes their offering strong for manufacturing firms in Malaysia.

A Manufacturing ERP consolidates key production processes so your company can:

- Plan materials and capacity more accurately (reducing stock-outs or excess inventory).

- Switch production routes quickly (alternative routing) and gain flexibility.

- Use mobile/IoT integrations to monitor production in real time, reducing downtime and waste.

These improvements contribute to leaner operations and better cost control.

Before investing in a Production ERP or Manufacturing ERP, check:

Does it support your manufacturing mode (discrete vs process) and complexity of BOMs? SL Information supports up to 50 levels of BOM.

Does the ERP provider have local experience and support in Malaysia? SL Information has decades of track-record.

Is the system scalable and able to integrate with modern technologies (IoT, mobile, RPA)?

Considering these factors helps ensure that you choose the “best ERP for manufacturing” for your business.